| Sign In | Join Free | My qualitytoyschina.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My qualitytoyschina.com |

|

Brand Name : MENTO

Model Number : S2020

Certification : FCC.ROHS,CCC

Place of Origin : DONGGUAN

MOQ : 1

Supply Ability : 10pcs+20 work days

Delivery Time : 20 work days

Packaging Details : 1200mm*1500mm*1800mm

Inspection Type : 2D and 3D

Lighting Source : UV and white light

Inspection Accuracy : ±3μm

Inspection Resolution : 10μm

Power Supply : AC 100-240V, 50/60Hz

Software Platform : Windows

Inspection Range : Up to 510mm x 510mm

Dimensions : 1000mm x 1000mm x 1500mm

Usage : Automated Optical Inspection

Inspection Speed : Up to 1200mm/s

Lighting Type : LED

S2020 Semiconductor wire bonding inspection

| Device model | S2020 | ||

| Detection capacity | Detection items | Wire bonding inspection | |

| Detection type | Ball size, solder offset, solder bridging, miss planting ball, particle, solder overlap, solder break, , welding wrong wire, wire break, wire collapse, wire bridging, wire residue, welding wire interleaving | ||

| Optical system | Camera | 20MP | |

| Telecentric lens | telecentric optical lens | ||

| Resolution | 4um(2.4um~4um optional) | ||

| illuminant | RGB(can be customized) | ||

| Efficiency | 3FOV/s | ||

| Software system | Operating system | Ubuntu | |

| Computer configuration | Host | CPU: Inteli7, RAM: DDR4-128G, GPU: GTX1660-6GB SSD:250G, HDD: 2T | |

| Monitor | 22"LED | ||

| Operating system | Ubuntu | ||

| Detection performance | PCB Thickness | 1~5mm | |

| Component Height | 20mm upper, 30mm lower (special height can be customized) | ||

| Driving equipment | Linear motor + grating ruler | ||

| Moving speed | Max:600mm/s | ||

| PCB transport rail | 900+20mm (from the ground to the fixture surface) | ||

| Parameters | PCB size | Max:350mmx300mm | Max:370mmx350mm |

| Power | AC220V/50Hz/2000W | ||

| Overall size | W1120xD980xH1600 mm | ||

| Weight | ≈800KG | ||

| Air pressure requirements | ≥0.5Mpa | ||

| Environmental requirements | Temperature: 5~40℃, relative humidity 25%~80% (no frost) | ||

| Upstream and downstream equipment communication | Standard SMEMA interface/data communication with die bonding machine | ||

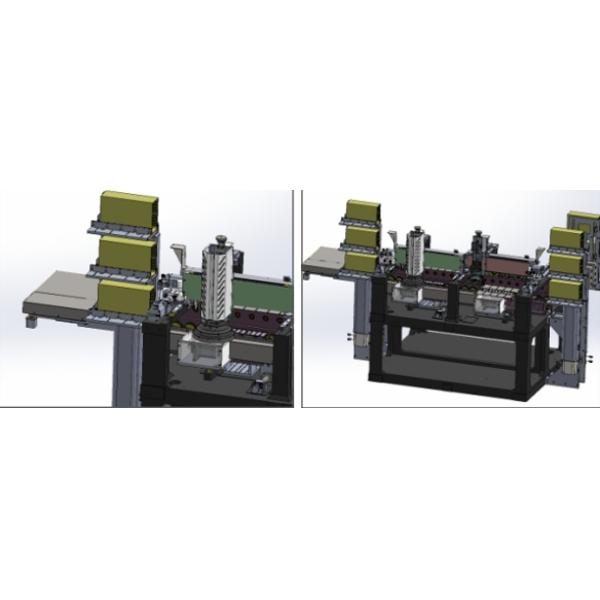

Scientific platform design

Grinding grade motion track design

High repeatability and positioning accuracy, low noise

High-precision motion control system design

Avoid motion system data loss, ensure high-speed and stable operation, and effectively improve motion acceleration and deceleration.

Overall casting structure

Effectively ensure the stability of the continuous operation of the equipment.

Inspection Items

Gold Wire Inspection:Ball size, solder offset, solder bridging, miss planting ball, particle, solder overlap, solder break, , welding wrong wire, wire break, wire collapse, wire bridging, wire residue, welding wire interleaving.

Core inspection: offset, rotation, particle, scratches, reverse and so on.

|

|

AOI Semiconductor wire bonding inspection for die bonding machine and track design Images |